Through our systematic production of prefabricated bathrooms, we ensure trouble-free construction progress and technical feasibility with full cost control. The speed of the weather-independent prefabrication in our factory is particularly convincing.

Jürgen Tillmann

Managing Director HBS HELLWEG BADSYSTEME GmbH

Prefabricated bathroom construction

Save time and money through prefabrication

Our prefabricated bathrooms are completely individually prefabricated in the factory according to your wishes and specifications. The compact room units with their own walls, floors and ceilings are fully equipped at the factory (wall and floor coverings, sanitary facilities, heating, ventilation and electrical installations, etc.) and delivered to the construction site turnkey. Normally, no work is required inside the baths, on site.

In a production process that has been tried and tested over decades and is constantly being refined, extremely robust and torsion-resistant monolithic room units are created. The proverbial resilience of concrete is the backbone of our solid bathroom construction. It easily defies adverse conditions during the shell construction phase. In operation, it is the prerequisite for technically problem-free operation and a visually appealing appearance over many years.

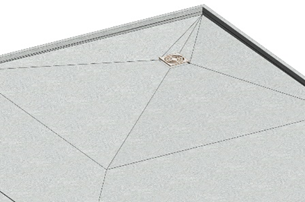

floor construction

The floors of HBS prefabricated bathrooms are made of steelreinforced concrete or lightweight concrete in special moulds.

The bathrooms are mounted directly on the raw ceiling. Mounting material to compensate for body shell tolerances and rubber pyramid bearings for sound decoupling are of course included in our scope of delivery. These elastomer bearings are dimensioned in the course of the work planning, based on your specifications, and ensure a safe reduction of Impact sound transmission and structure borne noise transmission.

The combination of a fully DIN-compliant composite sealing system with a watertight concrete trough with a surrounding upstand ensures the highest level of security in terms of watertightness.

Flush-to-floor showers can be manufactured easily and extremely inexpensively. Gradients with any course can be realized according to your wishes and requirements.

wall construction

Our walls are made of steel-rated normal or lightweight concrete. The normal wall thickness is only 50mm.

Due to the production in smooth steel formwork, the outside wall surfaces of the bathrooms on the room side can also be reused directly. Additional sheathing or cladding, e.g. with drywall panels, is not required.

The robust concrete construction allows for subsequent assembly of handles and other equipment without special substructures.

The walls of our prefabricated bathrooms can easily take on structural requirements. By simply varying the wall thicknesses, almost any fire or noise protection requirements can be met.

Any surfaces such as ceramic tiles, natural stone or glass wall coverings, painted surfaces and much more are possible indoors.

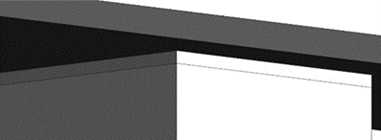

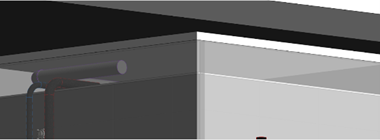

ceiling construction

The ceilings of HBS prefabricated bathrooms are also made of steel-reinforced concrete or lightweight concrete. Depending on the planned storey height, the bathrooms can be built virtually room-high. There is only a minimal gap to the overlying raw ceiling to accommodate subsequent ceiling deflections and the resulting sound bridges and static loads.

Depending on the requirements, a hollow space can be provided in the form of a suspended ceiling for media lines (ventilation, heating, cooling, electricity, etc.). If desired, even the most complex components and cable routings can be prefabricated in the factory and delivered to the construction site ready for connection. If desired, the ceilings can be used as lost formwork for an in-situ concrete ceiling. We will be happy to coordinate the exact procedure with you if necessary.

Montage

Our prefabricated bathrooms are delivered to the construction site by truck. Delivery and assembly are carried out just in time according to precisely coordinated schedules, depending on the progress of construction. With the help of a construction site or mobile crane, the pools are set down at their final destination, regardless of the weather.

Only the connection to the respective supply lines for drinking water and waste water, ventilation, heating and electricity must be made on site.

Equipment according to customer requirements individually

Even with the equipment, the production is completely individual. Builders and planners thus have the opportunity to implement their ideas with almost no restrictions. Whether luxurious, puristic, design-oriented or simple and functional, everything is possible. You are free to choose from all variants and products on the market.

On request, based on our many years of experience, we are happy to advise you with suggestions and alternatives.

You are also free to choose the technical trades. Electrical fittings, heating and ventilation components and so on are planned and produced according to your requirements.